Incidents drive new investments

A major builder is investing $1.2 million in safety after two severe incidents.

A major builder is investing $1.2 million in safety after two severe incidents.

Pledges have been made following recent Melbourne and Dandenong Magistrates' Court hearings in which construction company McConnell Dowell faced seven charges for workplace safety failures.

WorkSafe stipulated that charges could be reinstated if McConnell Dowell withdraws or breaches its enforceable undertaking.

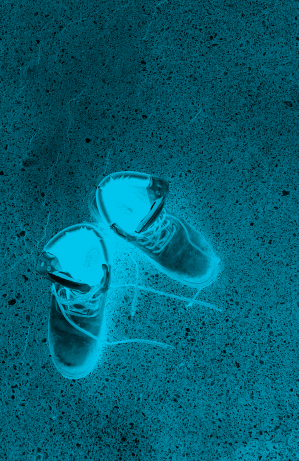

The first incident, in October 2021, involved a worker who suffered multiple injuries, including toe amputation and fractures, after being struck by a reversing dump truck on the Dandenong Level Crossing Removal Project.

WorkSafe alleged that McConnell Dowell failed to establish sufficient safety protocols, neglected to supervise workers adequately, and did not review work method statements when risks increased.

In a separate incident in January 2022, a labour hire worker was hit by an excavator at a Laverton project site, fracturing his foot and requiring weeks of recovery.

WorkSafe claimed the company did not prevent the risk of mobile plant accidents, especially for high-risk construction tasks.

Under the $1,254,708 enforceable undertaking, McConnell Dowell will implement Blindsight AI technology across its machinery and subcontractor equipment to manage separation between people and machinery, producing industry-wide training videos on the technology’s benefits.

Additionally, virtual reality units will train about 300 workers on plant-related risks, and will be made available to Box Hill TAFE and other industry operators.

A ‘Safe Sites’ campaign is also planned, including 14 safety training videos and the development of digital software for managing vehicle and pedestrian safety plans, alongside training for site supervisors.

McConnell Dowell will also fund an audit tool to address psychosocial risks and support Wellness in Infrastructure's six safety workshops.

Other commitments include $89,249 to RMIT for an Applied Science (Built Environment) scholarship, $35,000 to RMIT’s Safety and Health Innovation Network, and $56,000 to Women in Safety’s mentorship program.

WorkSafe’s Executive Director of Health and Safety Sam Jenkin remarked that separating mobile machinery from workers is critical.

“These incidents should serve as a major wake-up call to this company and to others that it is simply unacceptable for pedestrians and mobile plant to be operating in the same space,” he said.

WorkSafe recommends workplaces employing mobile machinery establish clear traffic management plans, maintain separation barriers, ensure lighting, consult staff on safety concerns, and regularly inspect machinery.

Print

Print